*Under the List of Accepted Papers, see Theme 14 - Case Histories, No. (222): "Geotechnical Investigation of Urban Roads with Composite Pavement Structure Using Destructive and Non-Destructive Testing" by Maziar Moaveni, Abbas Butt, Satish Gundapuneni, Adam Groves, Sean Widener

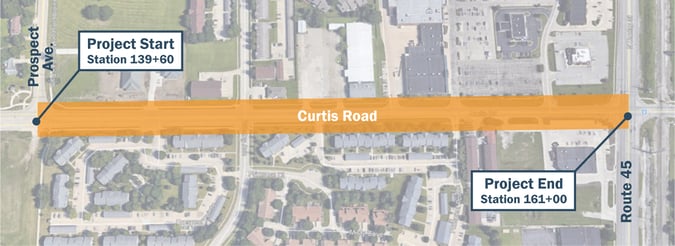

Geotechnical investigation for Curtis Road

The study provides findings from the geotechnical investigation performed on the existing pavement and within the right of way of the proposed lane widening for the Curtis Road project from Prospect Avenue to Route 45 in Savoy, IL. A comprehensive pavement analysis was performed using destructive (pavement coring/borings) and non-destructive testing (falling weight deflectometer and ground-penetrating radar).

First, let’s talk about destructive testing.

Pavement cores are drilled at pre-selected locations at various intervals in each lane. Soil investigation is necessary to determine the suitability of in-place soils as embankment and pavement subgrade. Soil properties determined from laboratory testing provide inputs for the pavement design such as the depth of various soil layers, moisture content, subgrade support rating, etc.

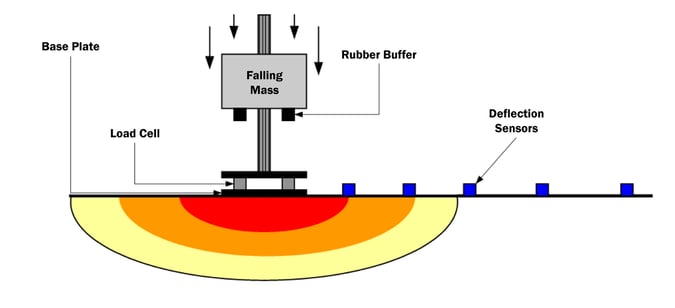

How does non-destructive testing work?

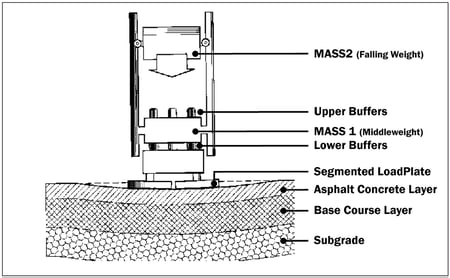

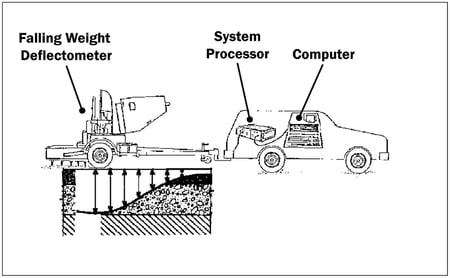

Non-Destructive Testing (NDT) using a Falling Weight Deflectometer (FWD) is conducted to measure the pavement’s structural response to heavy dynamic loads, similar in magnitude and duration to those produced by moving truck wheel loads. The deflection data collected is used to determine the pavement layer material properties, foundation support and divide the total length of the project into multiple uniform sections that exhibit similar responses under a given load. The FWD exerts an impulse loading force to the pavement and measures the resulting surface deflections. These deflections form a deflection basin. Ground Penetrating Radar (GPR) is an effective tool for quickly collecting the pavement surface thickness data while traveling at posted speed limits. The GPR system is capable of collecting data at intervals as small as 1 inch. Therefore, continuous pavement surface thickness profiles can be developed without causing any damage to the pavement structure. The FWD and GPR can be performed simultaneously by integrating both systems.

How both techniques work together in analysis

The FWD used the pavement, aggregate base, subgrade layers thicknesses from the GPR, and pavement coring in calculating the modulus values of each layer. Structural capacity of the existing pavement is calculated from the back calculation of modulus values from deflection data (View our Deflection Data Graph).

The project section (2300 ft.) of Curtis Road was divided into 5 uniform sections based on deflection data and pavement surface types. Based on the findings from the study, milling and overlay with localized patching and joint repairs were recommended for sections 1, 2, and 3. A full pavement reconstruction was suggested for sections 4 and 5. Where lane widening is required, it was suggested that the subgrade improvement should be performed by treating the top 12 inches of subgrade with lime.

Cost savings from our pavement testing approach

The findings from this showed that the combination of destructive and non-destructive testing can be effectively used to characterize the composite pavement structure. Sections 1, 2, and 3 do not need a complete reconstruction and are made up of 55% of the total project length. As a result, these methods helped in saving the overall cost of the project. We always look for ways to lower costs for our clients while maintaining a quality product.

Thanks to ERI* for your partnership!

We appreciate the success of this collaborative project and partnership with ERI. Thank you to Maziar Moaveni, Ph.D., P.E. and Abbas Butt, Ph.D., P.E. for your contributions to this paper. We're grateful to work with you in creating quality of life for our communities.

*Engineering and Research Int’l, Inc. (ERI) is a civil engineering firm committed to excellence in the field of pavement engineering. Nine specialized companies make up the ERI group to offer integrated geosciences services. Learn more about ERI.